Welcome to the Ultimate Guide to Strapping Tools!

Welcome to the Ultimate Guide to Strapping Tools!

In today's fast-paced world of shipping, logistics, and industrial packaging, ensuring the safe and secure transportation of goods is of utmost importance. The right strapping tools play a crucial role in achieving this goal, helping you bundle and fasten packages efficiently, reliably, and with optimal strength.

Whether you are a seasoned professional looking to upgrade your strapping equipment or a newcomer seeking to master the art of strapping, this comprehensive guide is tailored just for you. Here, we'll take you on a journey through the world of strapping tools, exploring everything you need to know to make informed decisions and streamline your packaging process.

From basic strapping terminologies to in-depth insights into various types of strapping tools, we'll cover it all. Our guide will walk you through the different strapping materials available, such as polypropylene, polyester, and steel, and how to select the most suitable one for your specific needs.

Discover the latest advancements in strapping technology and learn about innovative tools that are revolutionizing the industry. We'll introduce you to the cutting-edge tools designed to enhance efficiency, reduce downtime, and improve overall productivity.

No matter if you're looking for manual strapping tools for small-scale operations or high-performance automated strapping machines for industrial warehouses, we've got you covered. Our guide will help you understand the unique benefits of each type of tool, making it easier for you to choose the perfect match for your business requirements.

Beyond tool selection, we delve into essential tips and best practices for strapping applications in a separate blog post. Learn about proper tensioning techniques, the importance of choosing the right strapping seal or buckle, and how to ensure your strapping is tight and secure to withstand the rigors of transit.

Additionally, safety is always a priority when working with strapping tools, and we'll provide you with essential safety guidelines and precautions to follow, ensuring a hazard-free working environment for you and your team.

Are you ready to become a strapping expert? Let's dive into the world of strapping tools together and unlock the knowledge and skills you need to master the art of secure and efficient packaging. Whether you're a packaging professional or a business owner overseeing shipping operations, this guide is your gateway to elevating your strapping game and optimizing your packaging process. Let's get started!

The Importance of Strapping Tools in Packaging and Shipping

In the world of packaging and shipping, the role of strapping tools is paramount to ensure the safe and secure transportation of goods. Strapping, also known as banding or bundling, involves the process of fastening and securing packages, cartons, or pallets using straps made from various materials such as polypropylene, polyester, or steel. These straps are then tightened and sealed with the help of specialized strapping tools, which serve a crucial purpose in the overall packaging process. Let's explore the significance of strapping tools and their impact on the efficiency and reliability of packaging and shipping operations.

Secure and Damage-Free Transportation:

One of the primary reasons strapping tools are indispensable in packaging and shipping is their ability to provide a strong and secure bond between packages. Properly applied strapping ensures that goods remain tightly bundled during transit, reducing the risk of packages shifting, opening, or becoming damaged. By minimizing the likelihood of package breakage, strapping tools significantly contribute to reducing product loss and potential customer dissatisfaction.

Enhanced Package Stability:

Strapping tools enable precise tensioning of straps, resulting in optimal package stability. This stability is especially crucial for large, irregularly shaped, or heavy items that might be challenging to handle during transportation. Properly strapped packages are less prone to toppling over or becoming unstable in storage, thereby safeguarding both the products and the people handling them.

Improved Warehouse Efficiency:

Efficient strapping tools streamline the packaging process and enhance warehouse productivity. Whether using manual tensioners and sealers or automated strapping machines, these tools expedite the strapping process, allowing packaging professionals to complete their tasks swiftly and with precision. Faster packaging translates to quicker turnaround times, increasing overall efficiency and throughput in warehouses and distribution centers.

Cost-Effectiveness:

Investing in quality strapping tools can result in significant cost savings in the long run. Properly secured packages reduce the risk of damage, minimizing the need for rework or product replacements. Moreover, using the right strapping tools ensures that the appropriate amount of strapping material is used for each package, avoiding wastage and optimizing material utilization.

Versatility for Different Materials:

Strapping tools are adaptable to various packaging materials, including polypropylene, polyester, and steel strapping. This versatility allows businesses to select the most suitable strapping material based on the nature of the goods and the transportation requirements. With the right strapping tool, businesses can confidently secure packages of all shapes and sizes, from small cartons to heavy industrial equipment.

Compliance and Safety:

Strapping tools play a vital role in ensuring compliance with industry standards and safety regulations. Properly strapped packages are less likely to cause accidents or injuries during handling and transportation. Additionally, using high-quality strapping tools minimizes the risk of strap breakage, which could otherwise lead to hazardous situations for workers and the public.

In conclusion, strapping tools are indispensable assets in the world of packaging and shipping. They enhance the security, stability, and efficiency of packaging operations, reducing the risk of damage, optimizing material usage, and ensuring compliance with safety standards. By investing in reliable and appropriate strapping tools, businesses can ensure the safe and successful transportation of goods, ultimately fostering customer satisfaction and maintaining their competitive edge in the market.

Overview of Different Strapping Materials

Overview of Different Strapping Materials

Strapping materials are essential components in the packaging and shipping industry, designed to secure and bundle goods for safe transportation and storage. Different strapping materials offer unique properties and advantages suited for various applications. Here, we present an overview of the most commonly used strapping materials:

Polypropylene (PP) Strapping: Polypropylene strapping, also known as PP strapping, is a popular and cost-effective choice for light to medium-duty applications. It is lightweight, flexible, and easy to handle, making it ideal for securing packages, cartons, and bundles in industries such as e-commerce, retail, and small-scale shipping. Although PP strapping offers good elongation and initial tension, it is not recommended for heavy or high-tension applications due to its lower tensile strength compared to other strapping materials.

Polyester (PET) Strapping: Polyester strapping, commonly referred to as PET strapping, is a high-tensile and strong strapping material. It offers excellent resistance to elongation and retains tension over time, making it suitable for securing heavy loads and goods with sharp edges. PET strapping is commonly used in industries such as construction, lumber, steel, and heavy machinery. It provides reliable and long-lasting bundling, making it an excellent alternative to steel strapping for certain applications.

Steel Strapping: Steel strapping is the strongest and most robust strapping material available. It offers exceptional tensile strength and is ideal for securing heavy-duty and sharp-edged loads. Steel strapping is commonly used in industries such as manufacturing, construction, and metalworking. It provides superior strength and security, making it suitable for withstanding rough handling and harsh environmental conditions. However, steel strapping can be challenging to handle and may require specialized tools for tensioning and sealing.

Woven Polyester Strapping: Woven polyester strapping is a specialty strapping material that offers the benefits of both PET and steel strapping. It provides high tensile strength and excellent resistance to elongation, similar to PET strapping. Additionally, woven polyester strapping features a unique woven pattern that enhances its flexibility and tear resistance. It is commonly used in heavy-duty applications, such as securing bricks, concrete blocks, and machinery.

Corded and Composite Strapping: Corded and composite strapping are innovative alternatives to traditional strapping materials. Corded strapping consists of polyester cords encased in a polymer coating, providing high tensile strength and flexibility. Composite strapping combines polyester and polypropylene to offer a balance of strength and affordability. Both corded and composite strapping are commonly used in industries where lightweight, high strength, and minimal stretch are essential, such as appliance manufacturing and logistics.

Each strapping material offers unique characteristics to cater to various packaging and shipping requirements. When selecting the appropriate strapping material, consider factors such as load weight, package size, transportation conditions, and budget constraints. Choosing the right strapping material ensures the safe and secure transport of goods, minimizing the risk of damage and maximizing efficiency throughout the packaging and shipping process.

Understanding Strapping Seals and Buckles

Understanding Strapping Seals and Buckles

In the realm of packaging and shipping, achieving a secure and reliable strapping closure is essential to ensure the safe transportation of goods. Strapping seals and buckles play a crucial role in this process, providing the necessary means to fasten and hold strapping materials firmly in place. Let's delve into the world of strapping seals and buckles to understand their types, functions, and importance in the packaging industry.

Types of Strapping Seals and Buckles:

Lapover Seals: Lap-over seals, are designed with an open end that allows the strapping to be inserted through the seal before tensioning. Once the strapping is tightened, the open end of the seal is crimped or pressed shut using a dedicated strapping tool. Lapover seals are commonly used with steel strapping and are available in various sizes to accommodate different strapping widths.

Semi-Open Seals: Semi-open seals are a versatile type of strapping seal that combines some of the features of both open and closed seals. They have a partially closed design, with one end open for easy insertion of the strapping before tensioning. Once the strapping is tightened, the open end of the semi-open seal is crimped shut using a strapping tool, providing a secure and reliable joint. Semi-open seals are commonly used with polypropylene and PET strapping and provide excellent holding power, making them suitable for medium to heavy-duty applications.

Snap-on Seals: Snap-on seals, are effortless to apply. They feature a unique design that allows them to snap onto the strapping quickly and easily. Snap-on seals are commonly used with steel strapping and are a popular choice for fast strapping in heavy-duty applications.

Serrated Seals: Serrated seals are specifically designed to enhance grip and prevent slippage of the strapping. They feature serrated edges that grip the strapping tightly, creating a secure and stable joint. Serrated seals are commonly used with steel strapping and are well-suited for heavy-duty applications.

Wire Buckles: Wire buckles are u-shaped metal fasteners used to secure the ends of polypropylene, polyester, or corded strapping. They are easy to use and require no special crimping tools for application. Wire buckles come in different sizes to match the corresponding strapping width, and they are commonly used in industries requiring lightweight and versatile strapping solutions.

Importance of Strapping Seals and Buckles:

Strapping seals and buckles are crucial components in the strapping process, providing the following key benefits:

Secure Fastening: Strapping seals and buckles create a secure and tight closure, preventing the strapping from loosening or slipping during transportation. This ensures that packages remain intact and secure throughout their journey.

Load Stability: Properly applied seals and buckles help maintain the tension in the strapping, enhancing the stability of bundled goods. This is particularly important for heavy or irregularly shaped loads that may be susceptible to shifting.

Versatility: With various types of seals and buckles available, strapping tools can be used with different strapping materials, making them adaptable to various packaging needs and applications.

Convenience: Some seals and buckles, such as push-type seals and wire buckles, are user-friendly and require minimal effort to apply. This convenience streamlines the strapping process, saving time and labor costs.

Quality Assurance: Utilizing appropriate and high-quality seals and buckles ensures the reliability of the strapping joint, reducing the risk of package damage and increasing customer satisfaction.

In conclusion, strapping seals and buckles are essential elements of the strapping process, providing secure and reliable closures for packages during packaging and shipping. Choosing the right type of seal or buckle based on the strapping material and application requirements is key to ensuring the safe and successful transportation of goods. With a well-matched combination of strapping material and closure method, businesses can optimize their packaging operations and protect their products throughout the supply chain.

Manual Strapping Tools

Manual Strapping Tools

In the fast-paced realm of packaging and shipping, the need for efficient, reliable, and cost-effective strapping solutions is paramount. Manual strapping tools, the backbone of many industries, provide a practical and versatile approach to secure packages, pallets, and goods for safe transportation.

Designed to be user-friendly and robust, manual strapping tools offer a wide range of applications, from lightweight carton strapping in retail settings to heavy-duty bundling in industrial environments. Whether you're a small business owner, a warehouse manager, or a logistics professional, understanding and utilizing manual strapping tools can significantly enhance your packaging efficiency and product security.

In this comprehensive guide, we will explore the various types of manual strapping tools available, including tensioners, sealers, and combination tools. You will gain insights into the functionality and advantages of each tool, as well as the compatible strapping materials for optimal performance.

We will also provide valuable tips and best practices on how to properly use manual strapping tools, ensuring a safe and effective strapping process that reduces waste and improves overall productivity.

Join us on this journey as we uncover the world of manual strapping tools and equip you with the knowledge and skills needed to streamline your packaging operations and elevate your shipping game. Whether you're a seasoned professional or new to the world of strapping, this guide is your gateway to mastering the art of manual strapping tools and achieving secure, efficient, and reliable packaging for your business needs.

Manual Tensioners: Types and Functionality

Manual Tensioners: Types and Functionality

Manual tensioners are essential tools in the world of packaging and shipping, designed to achieve the precise tension required for securing strapping materials around packages, cartons, or pallets. These versatile tools come in various types, each tailored to specific strapping materials and applications. Understanding the different types and functionalities of manual tensioners is crucial for optimizing the strapping process and ensuring secure and reliable bundling.

Manual Tensioner for Polypropylene (PP) Strapping: Designed for use with polypropylene strapping, manual tensioners for PP strapping are lightweight and user-friendly. They typically feature a ratchet mechanism or lever-action design, allowing users to apply tension with ease. As the tensioner is engaged, it tightens the strapping around the package, ensuring a secure and tight closure. Manual tensioners for PP strapping are commonly used in retail, small businesses, and light-duty applications.

Manual Tensioner for Polyester (PET) Strapping: Manual tensioners for polyester strapping offer robust and efficient tensioning for heavy-duty applications. PET strapping is stronger than PP strapping, and manual tensioners for PET are specifically designed to handle the higher tension requirements. These tensioners often feature a serrated feed wheel mechanism, allowing users to achieve the desired tension with minimal effort. Manual tensioners for PET strapping are widely used in industries such as construction, metalworking, and heavy machinery.

Manual Tensioner for Steel Strapping: Steel strapping demands significant tension to secure heavy and bulky loads effectively. Manual tensioners for steel strapping are heavy-duty tools capable of providing the high tension needed for this robust strapping material. They often incorporate a cam-action design or a geared feed wheel mechanism, allowing users to tighten the strapping efficiently and securely. Manual tensioners for steel strapping are commonly used in industries such as manufacturing, lumber, and steel processing.

Combination Manual Tensioner and Sealer: Combination tools, also known as combination manual tensioner and sealer, are versatile tools that combine the functions of both tensioning and sealing strapping. These all-in-one tools streamline the strapping process by allowing users to apply tension and then seal the strapping using the same tool. Combination tools are available for various strapping materials, including PP, PET, and steel, making them suitable for different applications across different industries.

Functionality of Manual Tensioners:

The primary functionality of manual tensioners is to achieve the proper tension in the strapping, ensuring a tight and secure closure around the package. Manual tensioners achieve this through various mechanisms, such as ratchet, lever-action, serrated feed wheel, cam-action, or geared feed wheel, depending on the strapping material and application.

Proper tensioning is crucial as it provides the following key benefits:

Secure Bundling: Adequate tension ensures that the strapping remains tightly wrapped around the package, minimizing the risk of shifting or coming loose during transit.

Load Stability: Tightly tensioned strapping enhances the stability of bundled goods, reducing the chances of packages toppling over or becoming unstable during handling and transportation.

Package Protection: Properly tensioned strapping distributes the force evenly across the package, reducing the risk of damage or compression to the contents inside.

Improved Efficiency: Manual tensioners streamline the strapping process, enabling workers to efficiently tension strapping with minimal effort, thereby increasing productivity and reducing labor costs.

In conclusion, manual tensioners are essential tools for achieving the appropriate tension in strapping materials, ensuring secure and reliable bundling for packages and pallets. By understanding the different types of manual tensioners and their functionalities, businesses can choose the right tool for their specific strapping material and application needs. Investing in high-quality manual tensioners enables efficient and effective strapping operations, leading to enhanced package protection and overall logistics performance.

Manual Sealers: Applications and Techniques

Manual sealers are indispensable tools in the packaging and shipping industry, designed to securely fasten and seal strapping materials, ensuring packages and bundles remain tightly bound during transit and storage. These versatile tools are available in various types, each catering to specific strapping materials and applications. Understanding the applications and techniques of manual sealers is essential for achieving a reliable and efficient sealing process.

Applications of Manual Sealers:

Polypropylene (PP) Strapping Sealers: Manual sealers for polypropylene strapping are commonly used in light to medium-duty applications. They work in conjunction with open or closed seals, providing a secure and reliable joint. PP strapping sealers are frequently utilized in retail, e-commerce, and small-scale packaging operations.

Polyester (PET) Strapping Sealers: PET strapping sealers are designed to work with polyester strapping, which offers higher tensile strength and is suitable for heavy-duty applications. These sealers create a tight and durable seal when used with closed or semi-open seals. They are often employed in industries such as construction, metalworking, and logistics.

Steel Strapping Sealers: Steel strapping sealers are heavy-duty tools specifically engineered to crimp steel strapping. They create strong and permanent seals when used with open or closed seals. Steel strapping sealers are essential in industries involving heavy machinery, lumber, and large industrial equipment.

Techniques for Using Manual Sealers:

Proper Alignment: To achieve a secure seal, ensure that the strapping is correctly aligned within the sealer. The strapping should be centered in the sealer's notch to ensure even pressure during the sealing process.

Correct Seal Selection: Choose the appropriate type of seal for the specific strapping material and application. Open, closed, semi-open, or push-type seals are available, each with distinct characteristics suited to different strapping types.

Tensioning: Before sealing, use a manual tensioner to apply the appropriate tension to the strapping. Proper tensioning ensures a tight and secure closure around the package or bundle.

Seal Positioning: Place the seal in the designated area of the sealer, ensuring it aligns with the strapping. The seal should be positioned to allow sufficient space for crimping and secure closure.

Crimping: With the seal in place, use the manual sealer to crimp the seal and strapping together. The sealer's mechanism creates a strong, reliable seal, effectively joining the ends of the strapping.

Inspection: After sealing, carefully inspect the seal to ensure it is properly closed and securely fastened. Avoid any gaps or irregularities in the seal, as this could compromise its holding strength.

By employing the correct manual sealer and following proper techniques, businesses can achieve a reliable and secure strapping closure, ensuring the safe transportation of goods and protecting them from damage. Investing in high-quality manual sealers and training employees on proper sealing techniques will enhance the efficiency and effectiveness of the packaging process, ultimately leading to improved customer satisfaction and successful logistics operations.

Combination Tools: Efficiency and Versatility

Combination Tools: Efficiency and Versatility

Combination tools are powerful and versatile devices that have revolutionized the strapping process in the packaging and shipping industry. As the name suggests, these tools combine multiple functions into one, typically incorporating both tensioning and sealing capabilities. This integration streamlines the strapping process, making it more efficient and user-friendly. Combination tools are available for various strapping materials, including polypropylene (PP), polyester (PET), and steel, and they offer numerous benefits in terms of efficiency and versatility.

Efficiency of Combination Tools:

Time-Saving: By combining tensioning and sealing functions, combination tools significantly reduce the time required to complete the strapping process. Users can apply tension to the strapping and immediately proceed to seal it without the need to switch between different tools.

Streamlined Operation: The seamless integration of tensioning and sealing functions in one tool eliminates the need for manual handling of multiple devices. This streamlined operation reduces the risk of errors and ensures a smoother, more consistent strapping process.

Enhanced Productivity: Combination tools enhance productivity by accelerating the strapping process and reducing the time spent on each bundle or package. This increase in efficiency allows workers to handle more strapping tasks in a shorter period, ultimately improving overall productivity.

User-Friendly Design: Combination tools are designed to be user-friendly, often incorporating ergonomic features for comfortable handling. The simplified operation and intuitive controls make them accessible to both experienced workers and those new to the strapping process.

Versatility of Combination Tools:

Compatibility with Various Strapping Materials: Combination tools are available in models that work with different strapping materials, such as PP, PET, and steel. This versatility allows businesses to use the same tool for a wide range of applications, regardless of the strapping material required.

Adjustable Tensioning: Many combination tools feature adjustable tension settings, allowing users to customize the level of tension applied to the strapping. This adaptability is beneficial when working with different package sizes or varying load weights.

Suitable for Multiple Industries: Due to their ability to work with different strapping materials and the versatility of tensioning and sealing functions, combination tools find applications in various industries, including retail, logistics, construction, and manufacturing.

Portable and Cordless Options: Some combination tools come in portable and cordless versions, providing flexibility and freedom of movement during strapping operations. These cordless models are ideal for applications where mobility is essential or when access to power sources is limited.

In conclusion, combination tools are efficient and versatile solutions that have transformed the strapping process, making it faster, more streamlined, and user-friendly. The integration of tensioning and sealing functions simplifies the strapping process, while their compatibility with different strapping materials and adjustable tension settings enhances their versatility. By investing in combination tools, businesses can optimize their strapping operations, improve productivity, and ensure secure and reliable packaging for their products during transportation and storage.

Strapping Cutters and Dispensers: Essential Tools for Efficient Packaging

In the world of packaging and shipping, strapping cutters and dispensers are indispensable tools that enhance the efficiency and convenience of the strapping process. These specialized tools are designed to handle strapping materials with ease, allowing workers to quickly and safely cut straps to the desired length and dispense strapping for hassle-free application. Let's explore the significance and benefits of strapping cutters and dispensers in various packaging operations.

Strapping Cutters:

Strapping Cutters:

Strapping cutters, also known as strap cutters or strapping shears, are tools specifically engineered to cut through various strapping materials cleanly and effortlessly. They come in different designs and blade types, catering to different strapping materials, such as polypropylene (PP), polyester (PET), and steel. Strapping cutters offer the following key advantages:

Precision Cutting: Strapping cutters are designed for precise and clean cuts, ensuring that strapping ends are neatly trimmed without fraying or causing damage to the material.

Safety: These tools feature specialized blade guards or safety mechanisms to minimize the risk of accidents during the cutting process, protecting users from potential injuries.

Time Efficiency: By providing efficient cutting capabilities, strapping cutters enable workers to quickly prepare strapping lengths for bundling or palletizing, saving time and improving overall productivity.

Versatility: Depending on the design, some strapping cutters can handle multiple strapping materials, making them versatile tools suitable for various packaging applications.

Strapping Dispensers:

Strapping Dispensers:

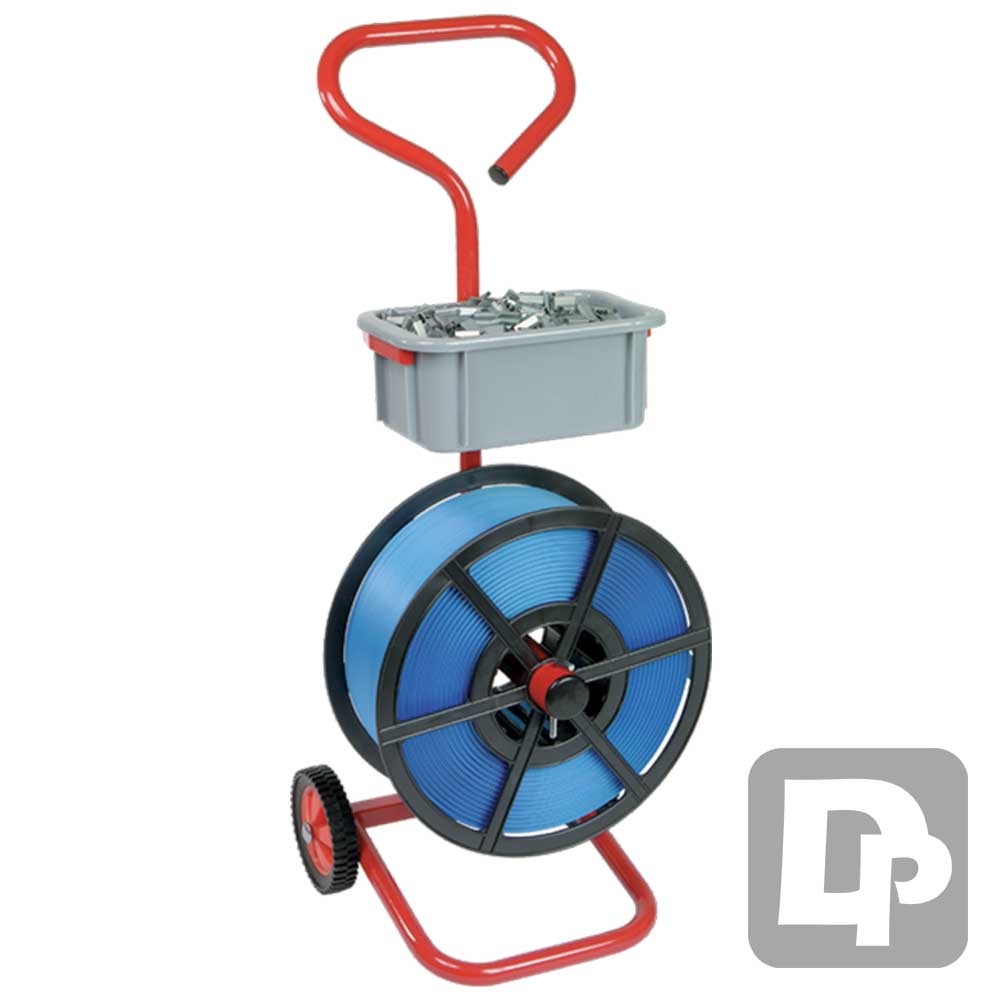

Strapping dispensers, also referred to as strapping carts or strapping trolleys, are essential tools used to hold and dispense strapping coils or rolls. These dispensers come in different configurations, ranging from compact handheld models to larger wheeled carts capable of holding heavy strapping coils. The key benefits of strapping dispensers include:

Easy Dispensing: Strapping dispensers are designed to smoothly dispense strapping, preventing tangles and ensuring a continuous and seamless strapping application process.

Enhanced Mobility: Wheeled strapping dispensers provide mobility, allowing workers to move the dispenser easily around the workspace, reducing the need to carry heavy strapping coils manually.

Neat Storage: Strapping dispensers help keep strapping coils organized and prevent them from unrolling or becoming tangled, promoting a tidy and efficient work environment.

Reduced Strain: By eliminating the need to lift and handle heavy strapping coils manually, dispensers reduce the risk of strain-related injuries among workers, promoting a safer workplace.

Combined Efficiency:

When strapping cutters and dispensers are used together, they create a harmonious strapping setup that optimizes efficiency and convenience. Workers can easily access strapping, cut it to the desired length with precision, and then apply it efficiently, all while maintaining a neat and organized workspace.

In conclusion, strapping cutters and dispensers are invaluable tools that significantly contribute to the efficiency, safety, and organization of the strapping process in packaging and shipping operations. By investing in high-quality strapping cutters and dispensers, businesses can streamline their packaging operations, improve worker productivity, and ensure the secure and reliable bundling of goods for transportation and storage.

Strapping Tool Accessories

In addition to strapping tools like tensioners, sealers, cutters, and dispensers, various strapping tool accessories are available to further enhance the strapping process, improve efficiency, and ensure the safe and reliable bundling of goods. These accessories are designed to complement the primary strapping tools and provide additional functionality and convenience. Let's explore some common strapping tool accessories and their roles in the packaging and shipping industry.

Strapping Protectors: Strapping protectors, also known as edge protectors or corner protectors, are essential accessories used to safeguard packages from damage caused by strapping tension. These sturdy, often plastic or cardboard-based, devices are placed at the edges or corners of packages to prevent the strapping from cutting into or damaging the contents. Strapping protectors help maintain the integrity of packages and ensure that the strapping does not crush or compress the items during transportation.

Strapping Carts and Dispensers: As mentioned earlier, strapping carts and dispensers play a crucial role in organizing and dispensing strapping coils or rolls. These accessories come in various sizes and configurations, including handheld models and wheeled carts. Strapping carts and dispensers enable smooth strapping application by ensuring that strapping remains tangle-free, easily accessible, and ready for use. They contribute to a more efficient workflow and reduce the risk of injuries associated with manually handling heavy strapping coils.

Strapping Tension Indicators: Strapping tension indicators, also known as tension meters or gauges, are tools used to measure the tension applied to strapping during the tensioning process. These devices provide a visual indication of the strapping tension, ensuring that it falls within the desired range for optimal bundling and package stability. Strapping tension indicators help prevent under- or over-tensioning, which can result in inadequate package security or potential damage to the contents.

Strapping Cutter Holsters: Strapping cutter holsters are convenient accessories that securely hold strapping cutters when not in use. These holsters typically attach to belts or tool belts, providing easy access to the cutter during the strapping process. By keeping the cutter within reach at all times, workers can save time and effort, as they won't need to search for the cutter when preparing strapping lengths.

Strapping Lubricants: Strapping lubricants are specialized products used to reduce friction during the tensioning process, particularly when working with steel strapping. Applying strapping lubricants to steel strapping helps to ease the tensioning process, reducing wear on the tool and extending its lifespan. These lubricants also aid in achieving consistent tension levels across multiple strapping applications.

- Strapping Pallet Probes: Strapping pallet probes, also known as pallet edge probes or pallet strapping guides, are valuable accessories used to ensure consistent and effective strapping of palletized loads. These probes are specially designed to fit into the gaps between the stacked layers of products on a pallet, creating a channel for the strapping to pass through.

Strapping tool accessories play a crucial role in optimizing the strapping process and ensuring the safe and efficient bundling of goods. From protecting packages and improving strapping application to measuring tension and providing organizational solutions, these accessories complement primary strapping tools to enhance productivity and maintain the integrity of packages during transportation and storage. Businesses can benefit from incorporating the appropriate strapping tool accessories into their packaging operations, creating a more streamlined and effective strapping workflow.

Conclusion

In the dynamic world of packaging and shipping, the use of strapping tools and their accompanying accessories has become indispensable. These tools and accessories play a pivotal role in ensuring the safe, secure, and efficient bundling of goods for transportation and storage. From manual tensioners and sealers to cutters and dispensers, each strapping tool serves a unique purpose, tailored to various strapping materials and applications.

Manual tensioners provide precise tensioning capabilities for polypropylene (PP), polyester (PET), and steel strapping, guaranteeing a tight and reliable closure. Paired with manual sealers, these tools create a seamless strapping process, offering efficiency and streamlining the workflow. Meanwhile, combination tools serve as all-in-one solutions, combining tensioning and sealing functionalities in a single device, boosting productivity and versatility across different strapping materials.

Incorporating strapping cutters into the packaging process ensures clean and accurate cuts, while dispensers keep strapping organized and easily accessible, reducing the risk of tangles and simplifying strapping application. Strapping tension indicators add an extra layer of control, allowing for precise tension measurements to optimize package security.

Additionally, strapping tool accessories like protectors, carts, holsters, lubricants, and pallet probes complement the primary tools, further enhancing the strapping process. Edge protectors safeguard packages, strapping carts and dispensers promote organization and mobility, cutter holsters facilitate easy access, lubricants reduce friction, and pallet probes ensure consistent and effective strapping on palletized loads.

Through the strategic use of these tools and accessories, businesses can achieve heightened productivity, increased load security, and reduced risk of package damage during transit. Worker safety is also improved, as ergonomic designs and safety features are incorporated into the tools, minimizing the risk of accidents.

In conclusion, strapping tools and accessories are vital components of modern packaging and shipping operations. From tensioners and sealers to cutters, dispensers, and various accessories, these tools collectively optimize the strapping process, contributing to efficient packaging, safe transport, and the preservation of goods' quality. By embracing the advancements in strapping technology and investing in high-quality tools, businesses can effectively safeguard their products throughout the supply chain and deliver a seamless customer experience.

Comprehensive Guide to Strapping Tools: Techniques, Applications, and Safety