- Products

- Protective Packaging

- Edge & Corner Protection

-

Foam Edge Protectors

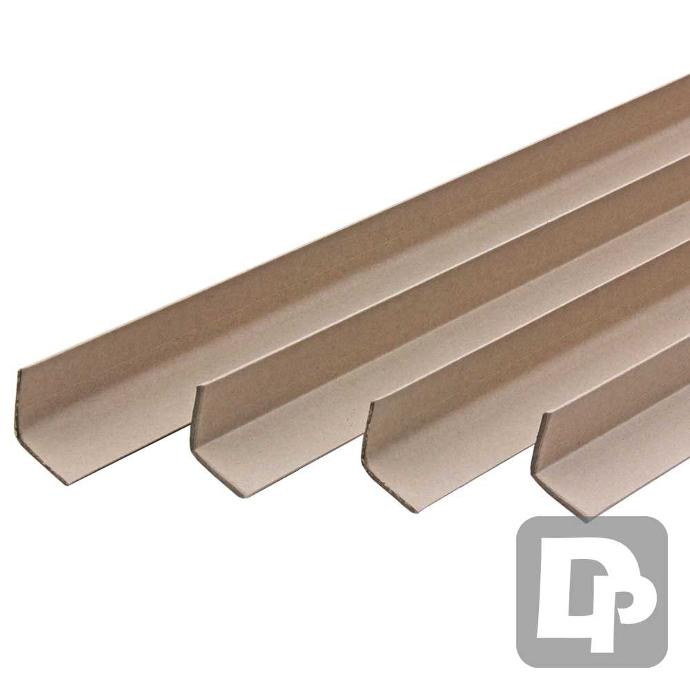

Corner Protectors & Edge Protection Strips

Corner protectors and edge protection strips are widely used across many industries for protecting corners and edges of finished products, pallets, and boxes from bumps and bashes, strapping indentions, and abrasions. Because corners and edges are at the extremity of any items they are the most vulnerable area and therefore are the areas that most needs protection. View Product Range

Edge Protection Strips for Packaging: Safeguarding Your Shipments

In the world of logistics and shipping, ensuring the safe transportation of goods is of utmost importance. Whether it's fragile electronics, delicate glassware, or heavy industrial equipment, the risk of damage during transit is always present. Edge protection strips have emerged as a critical solution in the packaging industry, offering enhanced protection and stability to packaged goods. In this article, we will delve into the significance of edge protection strips and explore their various applications and benefits.

What are Edge Protection Strips?

Edge protection strips, also known as edge protectors or corner protectors, are specially designed packaging materials used to safeguard the edges and corners of various goods during transportation and storage. They are typically made from materials like cardboard, paperboard, plastic, or foam, and are available in different shapes and sizes to suit specific packaging requirements.

The Role of Edge Protection Strips in Packaging

The primary function of edge protection strips is to prevent damage that may occur due to external forces such as impacts, compression, or abrasion. During transit, packages often go through a series of handling stages, including loading and unloading from trucks, conveyor belts, and sorting facilities. Without proper protection, the corners and edges of the packaged items are susceptible to denting, chipping, or even more severe damage.

By adding edge protectors to the packaging, the stress and pressure experienced during transportation are distributed evenly across the surface, reducing the likelihood of damage. This protective barrier can make the difference between a package arriving safely and intact versus a costly claim due to damaged goods.

Versatility and Customization

Edge protection strips offer a high degree of versatility and customization, making them suitable for a wide range of industries and applications. Manufacturers can tailor the shape, size, and material of the edge protectors to meet the specific needs of their products.

For instance, in the furniture industry, long and narrow edge protectors are commonly used to shield the edges of tables, cabinets, and chairs. On the other hand, industries dealing with large machinery or equipment may require more robust and durable protectors made from heavy-duty materials to handle the weight and provide extra protection.

Environmental Considerations

With increasing environmental consciousness, the packaging industry has been shifting towards more sustainable practices. Fortunately, edge protection strips can be manufactured from eco-friendly and recyclable materials, contributing to reducing the overall environmental impact of packaging.

Cardboard and paperboard edge protectors, in particular, are favored for their biodegradability and recyclability. This aligns with the growing demand from consumers and businesses alike for greener packaging solutions.

Cost-Effectiveness

While edge protection strips play a crucial role in safeguarding products, they also offer cost-effective benefits. The financial implications of damaged goods during shipping can be significant, leading to expenses related to returns, replacements, and potential damage claims. By investing in edge protectors, businesses can mitigate these risks, potentially reducing long-term costs and improving customer satisfaction.

Automated Packaging Solutions

As technology continues to advance, so do packaging processes. Many companies have embraced automated packaging systems to streamline their operations and improve efficiency. Edge protection strips are compatible with these systems, facilitating seamless integration and ensuring that packaging tasks are completed quickly and accurately.

Conclusion

In conclusion, edge protection strips have become an indispensable component of modern packaging solutions. They play a vital role in safeguarding goods during transit, reducing the risk of damage, and enhancing customer satisfaction. With their versatility, environmental friendliness, cost-effectiveness, and compatibility with automated packaging systems, edge protection strips are likely to continue being a staple in the packaging industry for years to come. As businesses seek to optimize their shipping processes and provide the best possible protection for their products, edge protection strips will remain a reliable and trusted solution.

Cardboard Corner Protectors: A Sustainable Shield for Safe Packaging

Cardboard corner protectors are primarily used for edge protection applications such as furniture protection, display protection, pallet stabilisation, and strapping protection. Cardboard corner protectors are a solid cardboard strip formed in a profile shape to fit around corners. The solid board construction makes these very strong and rigid, ideal for protecting against impact, pallet strapping idents, and for use as pallet corner posts. Our stock range of cardboard edging strips currently covers sizes in the 'L' profile range but the following profiles are also available to special order:

- 'U' Profile channel: Useful for containing lengths of strip or tube product as well as protecting regular thickness items like table tops etc.

- Notched Edging: This can be used for circular applications or for corners as the notched edging allows the corner to bend.

- Moisture Resistant: A cardboard edging that is used in damp conditions such as freezer warehouses and temperature controlled distribution.

Cardboard edge protection, also known as cardboard corner protectors, has emerged as a popular and eco-friendly solution for safeguarding goods during transit and storage. As businesses and consumers become more environmentally conscious, the demand for sustainable packaging materials has grown, making cardboard edge protection an attractive choice. Here we will explore the benefits and applications of cardboard edge protection in the packaging industry.

Benefits of Cardboard Edge Protection:

Environmentally Friendly: One of the most significant advantages of cardboard edge protection is its eco-friendliness. Cardboard is a renewable and biodegradable material, making it an ideal choice for those looking to reduce their environmental impact. Recycling cardboard is a straightforward process, contributing to the circular economy and reducing waste in landfills.

Effective Protection: Despite its eco-friendly nature, cardboard is surprisingly robust and provides excellent protection for packaged goods. By reinforcing the edges and corners of items, it prevents potential damages caused by compression, impacts, or mishandling during transportation.

Versatility: Cardboard edge protection is highly versatile and can be customized to fit various packaging needs. Manufacturers can create edge protectors of different sizes, thicknesses, and shapes to suit a wide range of products, from small electronic devices to large furniture pieces.

Cost-Effective: Cardboard is a cost-effective material, especially when compared to other protective options like plastic or foam. It offers a budget-friendly solution for businesses that want to provide added protection for their products without significantly increasing their packaging expenses.

Applications of Cardboard Edge Protection:

Furniture Industry: Cardboard edge protection is commonly used in the furniture industry to shield the edges and corners of tables, chairs, cabinets, and other bulky items. The protection ensures that these pieces arrive at their destination without unsightly scratches or dents.

Electronics and Appliances: Delicate electronic devices, such as televisions, monitors, and kitchen appliances, benefit from cardboard edge protection during shipping. The protectors prevent damage to the sensitive components and screens, preserving the products' quality.

Automotive Parts: Automotive manufacturers and suppliers use cardboard edge protection to safeguard various car parts and components during distribution. From headlights to bumpers, the protectors shield the edges, preventing potential damage caused by stacking or movement.

Glassware and Fragile Items: Fragile items like glassware, ceramics, and mirrors are prone to breakage during transit. Cardboard edge protection offers a reliable buffer, reducing the risk of chipping or shattering.

In conclusion, cardboard edge protection stands out as an effective, versatile, and sustainable solution for protecting goods in transit. Its eco-friendly nature, coupled with its ability to offer efficient protection, has made it a preferred choice for businesses seeking to enhance their packaging practices while minimizing their environmental impact. As sustainability continues to drive innovation in the packaging industry, cardboard edge protection is likely to remain a top contender in ensuring safe shipments and happy customers.

System 90 Pallet Corners

System 90 is a cardboard edge protection product available in a wide range of sizes and materials. Primarily used for pallet stability these edging strips can be used for a wide range of edge protection applications such as furniture protection, display protection and strapping protection.

Plastic Corner Protectors: Durable Shield for Secure Packaging

A range of plastic corner protectors for protecting corners of pallets, boxes, cabinets, and panels from impact or abrasion damage. Strapping corner protectors protect against strapping indent marks, and provide a firm corner to strap tightly onto; greatly increasing pallet stability. Expanding corner protectors are used for protecting the corners of panels and sheet materials; they expand to fit around the thickness of the panel. Plastic open corner protectors can be used for protecting the corners of larger items like cabinets.

We stock our plastic corner protectors in a range of different sizes to fit a whole selection of item sizes, choose from expanding corners that fit panels from 3mm up to 70mm, or strapping corner protectors that accept strap widths from 5mm up to 50mm.

Plastic corner protectors have become a reliable and widely used solution in the packaging industry, providing robust protection to the vulnerable corners and edges of goods during transit and storage. As a versatile and durable option, plastic corner protectors offer various benefits, making them a popular choice for businesses seeking to safeguard their products effectively. In this article, we will explore the advantages and applications of plastic corner protectors in packaging.

Advantages of Plastic Corner Protectors:

Strength and Durability: Plastic corner protectors are engineered to withstand substantial stress and pressure. They offer exceptional strength and durability, ensuring that the corners of packaged goods remain intact even when subjected to rough handling, stacking, or compression.

Resistance to Moisture and Chemicals: Unlike some other materials, plastic corner protectors are highly resistant to moisture and chemicals. This property makes them suitable for protecting goods that may be exposed to varying environmental conditions or during transportation involving hazardous substances.

Reusable and Recyclable: Many plastic corner protectors are designed to be reusable, further adding to their cost-effectiveness. When they reach the end of their lifecycle, they can be recycled, contributing to a more sustainable packaging approach.

Customizable Options: Plastic corner protectors come in various shapes and sizes, catering to a wide range of packaging needs. Manufacturers can customize these protectors to suit specific product dimensions and application requirements, ensuring a snug fit and optimal protection.

Applications of Plastic Corner Protectors:

Palletized Shipments: Plastic corner protectors are commonly used in the freight and logistics industry to secure palletized shipments. They prevent strapping and stretch wrap from directly contacting the product corners, reducing the risk of damage during transportation.

Metal and Industrial Goods: Industrial equipment, machinery, and metal products often have sharp corners and edges that require extra protection. Plastic corner protectors are an excellent choice to shield these items during handling and transit.

Glass and Mirrors: Fragile glass items like windows, mirrors, and glass panels are susceptible to chipping and cracking. Plastic corner protectors provide a cushioned barrier, preventing any direct impact on the corners and edges.

Furniture and Appliances: Plastic corner protectors are used extensively in the furniture and appliance industries. They safeguard items like sofas, refrigerators, and washing machines during shipping, reducing the chances of cosmetic damage.

In conclusion, plastic corner protectors offer a robust and dependable solution for safeguarding goods during packaging and transportation. Their strength, resistance to environmental factors, and customizability make them suitable for various industries and products. As businesses continue to prioritize secure and damage-free shipments, plastic corner protectors are likely to remain an essential component in the packaging toolkit, ensuring that goods reach their destination in excellent condition.

|

|

|